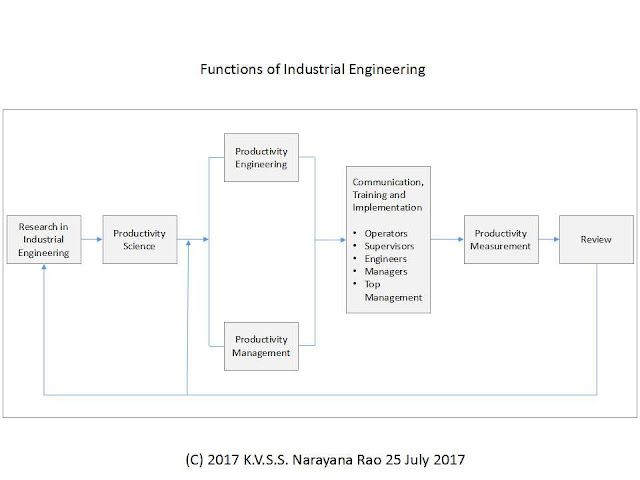

Productivity Science - Principle of Industrial Engineering

Develop a science for each element of a man - machine system's work related to efficiency and productivity.The productivity science developed is the foundation for industrial engineering in productivity engineering and productivity management phases.

http://nraoiekc.blogspot.com/2017/06/productivity-science-principle-of.html

Productivity Engineering - Principle of Industrial Engineering

Industrial engineering is concerned with redesign of engineering systems with a view to improve their productivity. Industrial engineers analyze productivity of each resource used in engineering systems and redesign as necessary to improve productivity.It has to be ensured that the increase in productivity due to the use of low-cost materials, processes and increasing speed of machines and men, should not lead to any decrease in quality of the output.

Similarly, operators should not feel any discomfort, not have any health problems or safety issues in the redesigned more productive processes.

https://nraoiekc.blogspot.com/2017/06/productivity-engineering-principle-of.html

IISE 2020 Conference Paper

Framework of Productivity Science

He has to plan for productivity and achieve productivity improvement year after year.

As a part of productivity management, he has to assess management actions of the organization for effect on productivity and has to recommend changes if they have an adverse effect on productivity or if there is scope for increasing productivity by modifying them.

https://nraoiekc.blogspot.com/2017/06/productivity-management-principle-of.html

Industrial Management Published Paper

Productivity Management- Principle of Industrial Engineering

Every industrial engineer is a productivity manager.He has to plan for productivity and achieve productivity improvement year after year.

As a part of productivity management, he has to assess management actions of the organization for effect on productivity and has to recommend changes if they have an adverse effect on productivity or if there is scope for increasing productivity by modifying them.

https://nraoiekc.blogspot.com/2017/06/productivity-management-principle-of.html

Industrial Management Published Paper

productivity management

https://nraoiekc.blogspot.com/2019/11/productivity-thinking-explanation.html

________________________

________________________

_______________________

Productivity Thinking - An Explanation

Productivity thinking of a manager includes awareness of body of knowledge of productivity science, productivity engineering and productivity management.https://nraoiekc.blogspot.com/2019/11/productivity-thinking-explanation.html

________________________

________________________

IISE Annual Conference Program 2019

Work Systems & Services

Oral Presentation (20 minutes)

580470 - Productivity Science and Systems - Developments During 1895 to 1945

Tuesday, May 21

11:20 AM - 11:40 AM

Location: Gatlin A2

Primary Contact(s)

Presenter(s)

Learning Objectives:

- F.W. Taylor described the system, he had used to increase productivity in 1895. More productivity improvement practices were described in his papers, "Shop Management" and "Scientific Management." Scientific management’s first principle advocates development of productivity science. Frank Gilbreth developed the science of productive human effort and proposed number of principles which became popular as "Principles of Motion Economy." In the paper, an attempt is made to highlight some important research works carried out in the area of productivity up to the year 1945 to trace the development of productivity science and systems after the need for developing them was indicated by F.W. Taylor. The purpose of the paper is to present an illustration of a collection of some scientific developments in productivity improvement that may motivate systematic development of body of productivity science in various issues related to productivity so that productivity engineering and productivity management activities are provided with scientific foundation for productivity improvement. Presently, an attempt to consolidate research output into productivity science is not taking place. Industrial engineering will have a more powerful knowledge framework if a well structured productivity knowledge base is made available as foundation for the phases of productivity engineering and productivity management.

- F.W. Taylor described the system, he had used to increase productivity in 1895. More productivity improvement practices were described in his papers, "Shop Management" and "Scientific Management." Scientific management’s first principle advocates development of productivity science. Frank Gilbreth developed the science of productive human effort and proposed number of principles which became popular as "Principles of Motion Economy." In the paper, an attempt is made to highlight some important research works carried out in the area of productivity up to the year 1945 to trace the development of productivity science and systems after the need for developing them was indicated by F.W. Taylor. The purpose of the paper is to present an illustration of a collection of some scientific developments in productivity improvement that may motivate systematic development of body of productivity science in various issues related to productivity so that productivity engineering and productivity management activities are provided with scientific foundation for productivity improvement. Presently, an attempt to consolidate research output into productivity science is not taking place. Industrial engineering will have a more powerful knowledge framework if a well structured productivity knowledge base is made available as foundation for the phases of productivity engineering and productivity management.

_______________________

Learning Objectives:

- F.W. Taylor described the system, he had used to increase productivity in 1895. More productivity improvement practices were described in his papers, "Shop Management" and "Scientific Management." Scientific management’s first principle advocates development of productivity science. Frank Gilbreth developed the science of productive human effort and proposed number of principles which became popular as "Principles of Motion Economy." In the paper, an attempt is made to highlight some important research works carried out in the area of productivity up to the year 1945 to trace the development of productivity science and systems after the need for developing them was indicated by F.W. Taylor. The purpose of the paper is to present an illustration of a collection of some scientific developments in productivity improvement that may motivate systematic development of body of productivity science in various issues related to productivity so that productivity engineering and productivity management activities are provided with scientific foundation for productivity improvement. Presently, an attempt to consolidate research output into productivity science is not taking place. Industrial engineering will have a more powerful knowledge framework if a well structured productivity knowledge base is made available as foundation for the phases of productivity engineering and productivity management.

- F.W. Taylor described the system, he had used to increase productivity in 1895. More productivity improvement practices were described in his papers, "Shop Management" and "Scientific Management." Scientific management’s first principle advocates development of productivity science. Frank Gilbreth developed the science of productive human effort and proposed number of principles which became popular as "Principles of Motion Economy." In the paper, an attempt is made to highlight some important research works carried out in the area of productivity up to the year 1945 to trace the development of productivity science and systems after the need for developing them was indicated by F.W. Taylor. The purpose of the paper is to present an illustration of a collection of some scientific developments in productivity improvement that may motivate systematic development of body of productivity science in various issues related to productivity so that productivity engineering and productivity management activities are provided with scientific foundation for productivity improvement. Presently, an attempt to consolidate research output into productivity science is not taking place. Industrial engineering will have a more powerful knowledge framework if a well structured productivity knowledge base is made available as foundation for the phases of productivity engineering and productivity management.

Engineering Management

Oral Presentation (20 minutes)

580223 - Evolution of Productivity Management - Present Scope, Opportunity and Challenges

Tuesday, May 21

8:20 AM - 8:40 AM

Location: Wekiwa 7

Primary Contact(s)

Presenter(s)

Learning Objectives:

- Frederick Taylor started productivity management theory development with his 1895 paper on piece rate system, and developed it further in "shop management" and "scientific management" papers. His methods were adopted in industrial engineering and operations management disciplines. Productivity, efficiency improvement and cost reduction as objectives of industrial engineering were indicated by many authors and scholars. AIIE also indicated the same by specially mentioning that performance from systems will be evaluated and predicted in industrial engineering. Scott Sink and David Sumanth came out with textbooks on productivity management. But a review of the curricula of industrial engineering and a survey reveal that productivity management is not yet an important area in teaching and practice. In this paper, an attempt is made to highlight the development of important productivity management theories and practices through literature review, curricula review, opinion of IE faculty and profit center managers. The current scope, opportunity and challenges for productivity management are brought out in the paper. The purpose of the paper is to point out the need for further development of the subject to convince academicians and practitioners of the utility of teaching and using productivity management systems and practices.

- Frederick Taylor started productivity management theory development with his 1895 paper on piece rate system, and developed it further in "shop management" and "scientific management" papers. His methods were adopted in industrial engineering and operations management disciplines. Productivity, efficiency improvement and cost reduction as objectives of industrial engineering were indicated by many authors and scholars. AIIE also indicated the same by specially mentioning that performance from systems will be evaluated and predicted in industrial engineering. Scott Sink and David Sumanth came out with textbooks on productivity management. But a review of the curricula of industrial engineering and a survey reveal that productivity management is not yet an important area in teaching and practice. In this paper, an attempt is made to highlight the development of important productivity management theories and practices through literature review, curricula review, opinion of IE faculty and profit center managers. The current scope, opportunity and challenges for productivity management are brought out in the paper. The purpose of the paper is to point out the need for further development of the subject to convince academicians and practitioners of the utility of teaching and using productivity management systems and practices.

https://www.eventscribe.com/2019/IISE/fsPopup.asp?Mode=presenterInfo&PresenterID=643406

----------------

Learning Objectives:

- Frederick Taylor started productivity management theory development with his 1895 paper on piece rate system, and developed it further in "shop management" and "scientific management" papers. His methods were adopted in industrial engineering and operations management disciplines. Productivity, efficiency improvement and cost reduction as objectives of industrial engineering were indicated by many authors and scholars. AIIE also indicated the same by specially mentioning that performance from systems will be evaluated and predicted in industrial engineering. Scott Sink and David Sumanth came out with textbooks on productivity management. But a review of the curricula of industrial engineering and a survey reveal that productivity management is not yet an important area in teaching and practice. In this paper, an attempt is made to highlight the development of important productivity management theories and practices through literature review, curricula review, opinion of IE faculty and profit center managers. The current scope, opportunity and challenges for productivity management are brought out in the paper. The purpose of the paper is to point out the need for further development of the subject to convince academicians and practitioners of the utility of teaching and using productivity management systems and practices.

- Frederick Taylor started productivity management theory development with his 1895 paper on piece rate system, and developed it further in "shop management" and "scientific management" papers. His methods were adopted in industrial engineering and operations management disciplines. Productivity, efficiency improvement and cost reduction as objectives of industrial engineering were indicated by many authors and scholars. AIIE also indicated the same by specially mentioning that performance from systems will be evaluated and predicted in industrial engineering. Scott Sink and David Sumanth came out with textbooks on productivity management. But a review of the curricula of industrial engineering and a survey reveal that productivity management is not yet an important area in teaching and practice. In this paper, an attempt is made to highlight the development of important productivity management theories and practices through literature review, curricula review, opinion of IE faculty and profit center managers. The current scope, opportunity and challenges for productivity management are brought out in the paper. The purpose of the paper is to point out the need for further development of the subject to convince academicians and practitioners of the utility of teaching and using productivity management systems and practices.

-----------------

Industrial Engineering ONLINE Course

Online Handbook of Industrial Engineering

________________________

________________________

Process Industrial Engineering - Video Presentation

https://www.youtube.com/watch?v=yIpkLPpsA18

Updated on 20 May 2021

Industrial Engineering ONLINE Course

Online Handbook of Industrial Engineering

________________________

________________________

Process Industrial Engineering - Video Presentation

https://www.youtube.com/watch?v=yIpkLPpsA18

Updated on 20 May 2021

12 November 2019, 16 September 2019

Productivity Engineering Taylor's Industrial Engineering in New Framework - Narayana Rao

ReplyDelete

ReplyDeleteFunctions of Productivity Management

ReplyDelete